Updated 03/10/2020

The Coronavirus COVID-19 is affecting solar module manufacturing and supplies worldwide. Supply chain managers, manufacturers and employers large and small are warning of substantial disruptions to their businesses. The virus has spread into the major economies of countries worldwide and economists are making dire predictions about the effect of the illness on the global economy. There remains huge uncertainty about how widely the virus will spread and how much more damage it will cause. However, the longer the shutdowns of Chinese production, and the more widely other countries are forced to take similar measures, the more the spread of the virus could affect the business of companies who rely on components manufactured overseas. Manufacturers and suppliers have already reached out to Artisan Electric warning of supply shortages beginning in May.

Where are solar panels made?

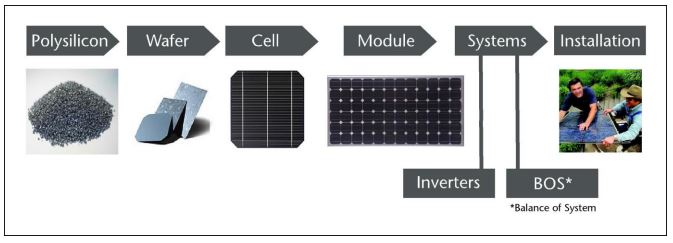

Currently, over 50% of the solar module manufacturing worldwide occurs in China. Companies based in, or having significant facilities in China and nearby countries also dominate manufacturing through the solar energy value chain. Although some solar PV modules are Made in the USA, such as Silfab, Mission Solar, LG and Q-Cell, these companies import components to manufacture their panels. REC Silicon previously manufactured polysilicon in Moses Lake, WA for the Chinese and domestic market, but closed after the solar tariffs made their business model nonviable. The US currently does not have any large-scale manufacturing facilities for wafer or cell production. This means that wafers and cells must be imported.

Internationally, manufacturers such as Hanwha Solutions Corporation, which produces Q CELLS, has temporarily shut down its two major module assembly plants in South Korea, due to raw materials and component shortages, usually purchased from China-based suppliers. Eight Chinese provinces have announced work stoppages because of the coronavirus. This is leading to supply shortages that will cause the cost of solar to go up in the near future.

Where are solar inverters made?

Enphase and Solaredge are two of the biggest inverter brands in the world. Enphase micro-inverters are designed in California and assembled in China. Solaredge is headquartered in Israel and their inverters are also manufactured in China. These are the primary brands supplying the Washington State market to meet the 2017 NEC Electrical Code requirements. Both companies have announced they are preparing for what could be a significant impact from the coronavirus in China, which has led to massive quarantines and an economic slowdown that could affect their manufacturing and supply chains.

How will the Coronavirus COVID-19 affect solar installations in Washington State?

Artisan is preparing for module and inverter shortages beginning early May of this year. If we run out of our preferred panels and inverters, we will have to either pay more for high-demand equipment of sell alternative brands.

Solar installations may also grind to a halt. Like all construction in Washington State, solar workers must perform their tasks in public settings; the work cannot be done remotely or outsourced. The solar industry in particularly vulnerable because solar is not a necessity and requires interacting with customers. If the coronavirus spreads to a point where movement is restricted for an extended period of time, many retail and construction companies will struggle to keep our doors open.

Overall, there is good reason to be wary of possible upcoming price increases or shortage of A-grade equipment due to supply shortages. In addition to increased cost, the variety of brand availability will be unpredictable. This means customers may not be able to specify a certain brand choice in the near future. Installation schedules could also be affected by an unpredictable product supply, which may cut into overall production – 80% of all solar production in Western Washington occurs between April-October.

What precautions is Artisan taking with staff and customers?

Artisan staff have been directed to follow basic health care protocols during this time, including frequent hand washing, covering coughs or sneezes with a tissue, to avoid touching their face and mouth and keep their work area and offices sanitized whenever possible. All staff have been directed to stay home if sick or symptomatic.

We are in contact with local health agencies to stay up-to-date on the status of COVID-19 in the city, and will consider measures recommended by them, including possible closures. We are increasing our sanitization efforts for the Artisan office, and placing additional hand sanitizer stations across our facilities.

If you’re thinking about solar – it’s best to schedule it soon. We will continue installing PV systems until movement restrictions are imposed. Module pricing and availability are currently unchanged, however the volatility of this situation changes on a daily basis.